<From 135 Years of Tradition to a Micron-Precision Future>

The Fusion of Light and Precision “Pioneering Japan’s Craftsmanship Technology”

Watanabe Gosando Co., Ltd. was founded in Osaka in 1890 as a plate-making company.

Our history has run parallel to Japan’s modern printing history. In our early days, all printing plates were crafted by hand. We drew lines with brushes and carved characters and designs with chisels, truly shaping information and designs through “handicraft.”

For over 130 years since then, our company has evolved alongside printing technology. From woodblock prints to lead type, photolithography, and now digital plate-making—while embracing significant technological shifts throughout the eras, we have consistently upheld the craftsman’s spirit of “creating original plates accurately and precisely.”

<Standardizing 10,000 dpi × 3 Micron Technology>

Ultra-Fine, High-Fidelity “Pre-Manufacturing Process” Technology

Currently, our company has established a technology for precisely depicting high-resolution data exceeding 10,000 dpi (dots per inch) onto photosensitive films and resin plates at a 3 µm (micrometer) resolution. This is equivalent to approximately 10 to 20 times the resolution of typical offset printing data, and it’s designed to meet the demands of high-end product manufacturing where even slight design errors or outline distortions are unacceptable.

While plate-making is conventionally understood as a “pre-process for printing,” we view this technology as a broader “structure formation technology.”

Some of the advanced fields our company currently supports include:

- Manufacturing of flexographic resin plates for functional packaging (high environmental performance and barrier properties)

- Hologram structure formation (security and design applications)

- Prototype processing of photomasks for electronic materials (touch panels, substrate circuits, RFID)

- Structural processing of microfluidic chips and bio-devices (medical and inspection applications)

Our technology extends beyond creating “visible” printed materials; we are now stepping into a world where we precisely create “invisible” structures and those “too precise for the human eye to confirm.”

<Developing Light-Manipulating Equipment and Accumulating Expertise>

“Light Design” Creates the Future of Plate-Making

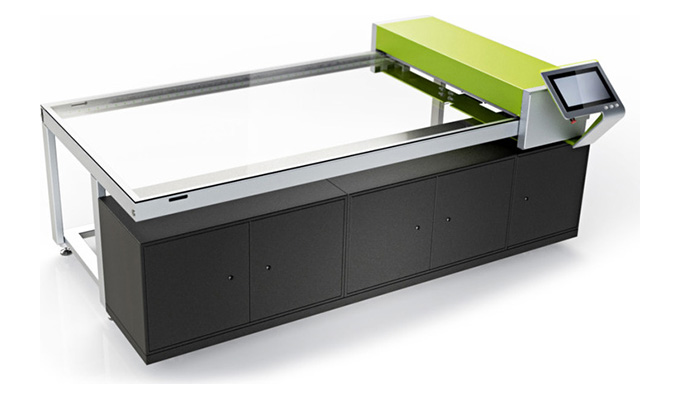

Our particular strength lies in exposure processing, the process of creating images with light. The technology of processing the surface of photosensitive materials like film and resin with laser light, and then irradiating them with ultraviolet (UV) light to induce a chemical reaction that fixes the data as a physical structure, is the core of plate-making.

At our company, we independently select, design, and customize high-power UV exposure equipment in the UVA (365nm) wavelength range, strictly managing irradiation uniformity, light intensity stability, and temperature characteristics. This ensures “reliable plate-making” where lines and dots, even just a few microns wide, are developed with absolute precision.

Furthermore, we are looking to apply this exposure technology to the increasingly prominent nano- and micro-patterning technologies. In the future, it holds potential for applications in pre-processes for semiconductor photolithography and the formation of functional films for medical use.

<Contributing to Green Printing and a Decarbonized Society>

Green Technology Expanding from “Printing Plates”

Our core technology, flexographic plate-making, offers excellent characteristics such as compatibility with water-based inks, solvent-free operation, and high-speed printing. It is rapidly growing in popularity in Europe and North America as an alternative to gravure printing.

To promote this “sustainable printing method” in Japan, we are one of the few leading players in high-precision flexographic plate-making domestically. We offer a three-pronged approach: equipment installation support, technical support, and material supply.

In recent years, we have also been working on printing plates that support Universal Media Design, enhancing compatibility with film and paper materials. We also focus on processing plate materials using a kansei engineering approach, considering visibility and tactile sensation. Our goal is to create plate-making that realizes “ease of use” and “human-friendly information transmission.”

<Our Message for Expo 2025 Osaka, Kansai>

“Plate-making Technology Creates the Future.”

For over 130 years, we have been dedicated to “creating original plates for accurate reproduction.” This technology has expanded beyond the world of printing, finding applications in diverse fields such as medicine, electronics, and environmental technology. Our plate-making technology creates precise forms in the invisible, micron-level world. This forms the foundation that will support future society.

At Expo 2025 Osaka, Kansai, an international stage, we aim to convey the value of this “original plate-making” to the world. And for the next 100 years, we will continue to shape the future with the power of light and the wisdom of our craftsmen.